Capacity Increase with Adiabatic Cooling

Application

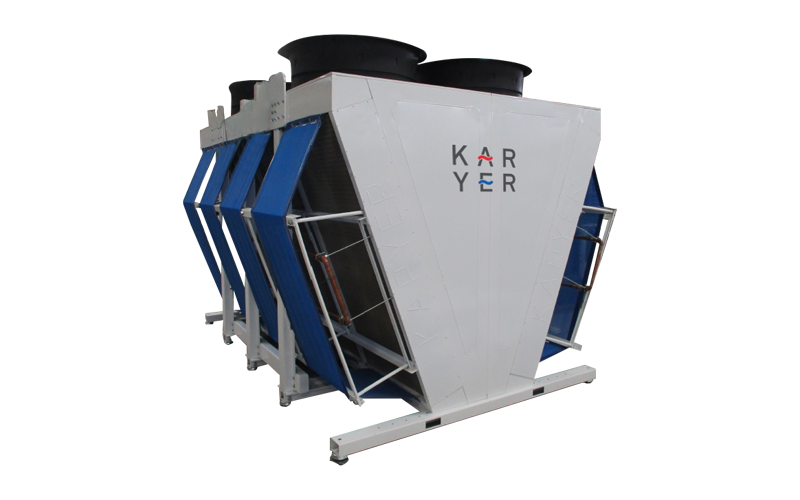

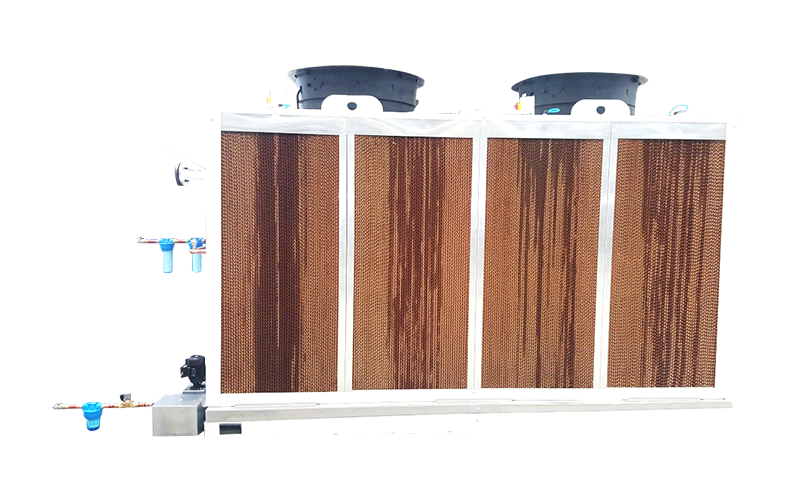

In order to increase the dry capacity in condenser and dry coolers, the latent heat of the water is used by adiabatic cooling and wetting.

In the air inlet of condenser and dry coolers, the air temperature is decreased with the help of plastic net (-M) and cellulosic pads (-A) wetted with water, water spraying (-S) or hybrid system (-AS) (adiabatic/wet) to increase the capacity. The product is encoded with the "-M, -A, -S, -AS” in its nomenclature. Spraying installation (excluding pump), pad installation (including pump) are in scope.

Heat exchangers are manufactured as OEM, taking into account the meteorological conditions at the place of installation, supply of water and water softening facility, installation space, energy and economic usage preferences.

Heat exchangers are designed from copper tubes / aluminum fins and painted galvanized sheet metal as standard. Fins can be offered precoated upon request.